News

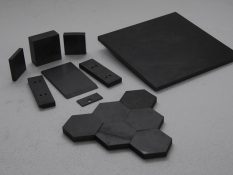

Boron carbide possess excellent features of high temperature oxidation resistance, high hardness, low density, high melting point and excellent wear resistance. Boron carbide is widely used in the field of refractory materials, wear-resistant materials and lightweight protective materials etc. Boron carbide is mainly used as an antioxidant and burning agent for refractories in refractories, the oxidation resistance of carbon-containing refractories can be significantly improved after the addition of boron carbide.

When added to carbonaceous refractories as antioxidants, boron carbide can not only enhances the thermal shock resistance of refractories, but also protects refractories from metal and slag infiltration to prevent the carbon in carbonaceous refractories from being oxidized. The reason why it can play this role is that when boron carbide is oxidized, it will interact with the substrate material to form a liquid or gas phase, thereby preventing the carbon in the carbonaceous refractory from being oxidized, which prolongs the service life of the carbonaceous refractory.

In addition to acting as an antioxidant, boron carbide can also be used as a burn-in promoter for refractory castables. The boron carbide oxidation product B2O3 melts into the liquid phase at a lower temperature, and promotes the densification of the material through liquid phase sintering. Tu Junbo et al. studied the effect of B4C admixture on the performance of Al2O3-SiC-Si3N4 iron trench castable. The results show that with the addition of B4C, the liquid phase of B2O3 generated by oxidation can promote the flow of substances, improving the density of the product and improve the properties of the material. The comprehensive performance of the iron trench castable reaches the best when the B4C plus mass fraction is 0.4%.

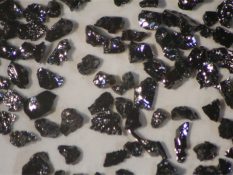

Boron carbide is a synthetic wear-resistant material with a hardness of 9.3 on the Mohs scale, making it one of the three hardest materials known.

Boron carbide combines many excellent properties including high hardness, low density, strong neutron absorption capacity, high melting point, high modulus of elasticity, low expansion coefficient and good oxygen absorption capacity, stable chemical properties, semiconductor conductivity and high grinding efficiency etc. Because of the above characteristics, boron carbide has become the main raw material for the manufacture of refractory materials, high-temperature resistant materials, wear-resistant welding rods, metal borides, boron alloys, engineering ceramics, boron steel and so on.

Especially when acting as an antioxidant, boron carbide plays a role in various fields of metallurgy as a high-grade shaped and amorphous refractory. In the steel industry, it is used in key parts of high temperature resistance and erosion resistance, such as steel stoves, kiln furniture, etc.

Boron carbide plays the effect of oxidation resistance in carbon-containing refractories to achieve the product high-density, blocking the oxidation of carbon in carbon-containing refractories. When under the temperature of 1000°C ~ 1250°C, the columnar crystals produced by the chemical reaction are distributed in the matrix and gaps of the refractory, leading to the porosity reduced, medium temperature intensity increased, at the same time, crystal volume expands, which can heal the volume shrinkage and reduce cracks.

Jun 16,2023

Bullet proof performance of silicon carbide vs Boron carbide ceramicPeople are universally impressed with the view that cer…

Jul 17,2023

Use of Boron carbide as chemical additiveBoron carbide (B₄C) is an inorganic substance, also kno…

Jun 09,2020

Grinding&Polishing Properties of Boron carbideBoron carbide is a highly valuable variety of…