News

People are universally impressed with the view that ceramics are fragile products. While ceramics act as a new material provided with high hardness and good strength after processing by modern scientific and technological means.

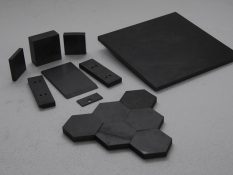

Since the 21st century, bulletproof ceramics have gained the booming development, expanded with diverse materials, including alumina, silicon carbide, boron carbide, silicon nitride, titanium boride, etc., among which alumina ceramics (Al2O3), silicon carbide ceramics (SiC), boron carbide ceramics (B4C) are widely used in various industries.

carborundum bulletproof ceramic

Silicon carbide is structured with extremely strong covalent bonds which maintain the high strength bonding at high temperatures. Carborundum ceramic is featured with relatively low density. With the property of high hardness, wear resistance, corrosion resistance, high thermal conductivity and good thermal shock resistance, carborundum ceramic is cost-effective among structural ceramics.

Due to the affordable price and good value for money, silicon carbide ceramics are one of the most promising high-performance armor protective materials, widely used in China as bulletproof ceramics .

Boron carbide bulletproof ceramics

In the currently known materials, boron carbide is a superhard material with a hardness second only to diamond and cubic boron nitride. With low thermal expansion coefficient and high thermal conductivity, boron carbide is also possessed of good chemical stability, which can resist both acid and alkali, not wetten or interacting with most molten metals.

With the lowest density and high modulus of elasticity among several commonly used armor ceramics, B4C is a good choice for materials in the military armor and space sectors.

However, boron carbide ceramics are demanding for processing technology, high temperature and high pressure sintering are required. Thus the cost of boron carbide ceramics is the highest among these three ceramics.

Alumina bulletproof ceramics

With lowest price among the three ceramics, the anti-ballistic performance of alumina bulletproof ceramics is far inferior, compared with silicon carbide and boron carbide. This is why currently silicon carbide and boron carbide bulletproof occupy a major position in domestic production units on bulletproof ceramics, while alumina ceramics are rare.

Jun 09,2020

Grinding&Polishing Properties of Boron carbideBoron carbide is a highly valuable variety of…

Jul 17,2023

Use of Boron carbide as chemical additiveBoron carbide (B₄C) is an inorganic substance, also kno…