Service

We prioritize the satisfaction of our customers above all else. We strive to understand your needs, exceed your expectations, and deliver exceptional service at every interaction.

Professional foreign trade team can provide you good service. And we have our own factory so that the price can be better.Any questions please feel free to contact us at any time.

With ISO9001 quality management system, all our products are manufactured by strict procedures.

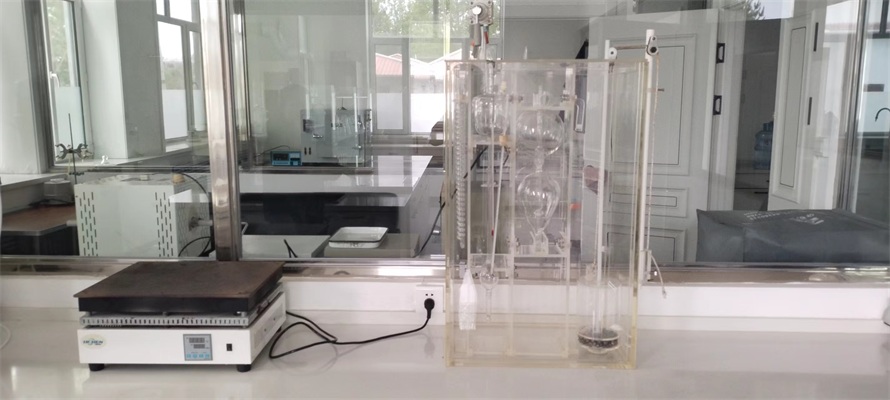

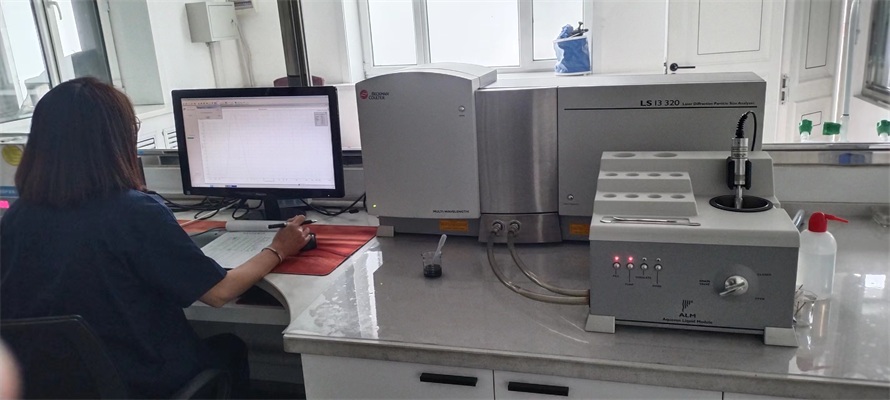

With the advanced test equipments in our Lab, all shipments are tested carefully before delivery to assure the quality consistency.

Our aim is to provide customers the high quality products, most competitive pricing, the shortest delivery time and the unequaled service.

Professional after-sales team provides customers with professional technical guidance and solutions.

Here are some problems you may encounter

Boron carbide powder is a compound made up of boron and carbon atoms. It is one of the hardest materials known to man and is often used in applications that require a high level of wear resistance, such as armor plate, and abrasives.

Boron carbide powder is used in a variety of applications, including:

1. Abrasives: Boron carbide powder is used as an abrasive in grinding, lapping, and polishing applications due to its high hardness and wear resistance.

2. Armor: Boron carbide powder is used in ceramic armor plates due to its ability to absorb high amounts of energy upon impact, making it highly effective against ballistic threats.

3. Nuclear applications: Boron carbide powder is used as a neutron absorber in nuclear reactors and nuclear weapons due to its ability to absorb neutrons without undergoing fission.

4. Refractory materials: Boron carbide powder is used in refractory materials, such as crucibles and furnace linings, due to its high melting point and chemical inertness.

5. Semiconductor manufacturing: Boron carbide powder is used in the production of semiconductors as a dopant material to control the electrical properties of the material.

Boron carbide powder has several unique properties that make it useful in a variety of applications, including:

1. High hardness: Boron carbide powder is one of the hardest materials known, with a Mohs hardness of 9.3.

2. Low density: Boron carbide powder has a low density, making it useful in applications where weight is a concern.

3. High melting point: Boron carbide powder has a high melting point of around 2,200°C, making it useful in high-temperature applications.

4. Chemical inertness: Boron carbide powder is chemically inert, meaning it does not react with most other substances.

5. High neutron absorption: Boron carbide powder is highly effective at absorbing neutrons, making it useful in nuclear applications.

Boron carbide powder should be handled with care, as it can be harmful if inhaled or ingested. It is important to wear appropriate personal protective equipment, such as gloves, a lab coat, and a respirator, when handling boron carbide powder. In addition, it is important to handle the powder in a well-ventilated area to avoid inhaling any dust particles. If boron carbide powder is ingested or inhaled, seek medical attention immediately.

Yes, boron carbide powder can be used in additive manufacturing, such as 3D printing. However, due to its high hardness and chemical inertness, it can be difficult to process using traditional additive manufacturing techniques. Researchers are exploring new approaches, such as laser sintering or electrostatic deposition, to overcome these challenges.

Boron carbide powder is available in a range of particle sizes, typically from less than 1 micron to several hundred microns. The particle size distribution can be controlled during the production process by adjusting the reaction conditions and post-processing steps.

Boron carbide powder is one of the hardest abrasive materials available, with a Mohs hardness of 9.3. It is harder than silicon carbide, aluminum oxide, and diamond, which makes it useful in applications where high grinding or polishing forces are required. However, it is less durable than diamond, which can lead to faster wear of the abrasive tool.

Yes, boron carbide powder can be used in additive manufacturing, such as 3D printing. However, due to its high hardness and chemical inertness, it can be difficult to process using traditional additive manufacturing techniques. Researchers are exploring new approaches, such as laser sintering or electrostatic deposition, to overcome these challenges.

Boron carbide powder is generally considered to be environmentally benign, as it is non-toxic and chemically inert. However, the production process can generate greenhouse gases and other air pollutants, depending on the energy source used. In addition, the disposal of boron carbide waste can pose a challenge, as it is a hard and durable material that does not readily degrade.

Raw Material (Boron Acid and Graphite) test -- furnacing -- crushing -- cleaning -- sieving or grading -- inspection -- packing