News

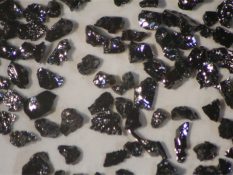

Boron carbide (B₄C) is an inorganic substance, also known as black diamond, usually presented in a black-gray powder which is one of the three hardest materials known. Boron carbide is often used in structural materials, ceramic materials, chemical raw materials, nuclear properties, electrical properties because of its high melting point, high hardness, low density, chemical stability, neutron absorption, etc.

Boron carbide can be used as an additive for some metal-based friction materials in chemical raw materials. Boron carbide is used as a boron source to prepare boride powder by chemical reduction, through which to manufacture boron halide and hydrogen boride, etc.

On the level of chemical raw materials, boron carbide is more universally used as a boronizing agent for steel or other alloys to infiltrate boron on the surface of steel, forming a thin layer of iron boride to enhance the strength and wear resistance of the material.

As a kind of infiltration, boron infiltration is a way to make the plating layer and the base metal form an alloy through a certain process, the plating does not fall off easily. After boron permeation processed, the boron layer has high hardness, high wear resistance, high hot hardness, good corrosion resistance and oxidation resistance, etc. Generally used processes include paste boron infiltration, solid powder boron infiltration, gas boron infiltration, salt bath boron permeation, in which the solid powder boron process is conveniently operated and quality is easily controlled through using the simpler devices, thus to be the most widely used boron process.

The solid boriding process is a boriding method in which the solid powder boriding agent and the workpiece are simultaneously loaded into the boriding container, the workpiece is buried in the boriding agent and the container is sealed; then the container is heated to the boriding temperature and kept warm for a certain period of time. Solid boriding agent is generally composed of boron supplier, activator and filler. Boron donor provides a stable boron source in the boron infiltration process through chemical reaction. In the domestic process, boron carbide, borax and etc material are usually adopted as solid boriding agents.

Jun 09,2020

Grinding&Polishing Properties of Boron carbideBoron carbide is a highly valuable variety of…

Jun 16,2023

Bullet proof performance of silicon carbide vs Boron carbide ceramicPeople are universally impressed with the view that cer…